Fully Welded Trunnion Ball Valve

1. Product overview

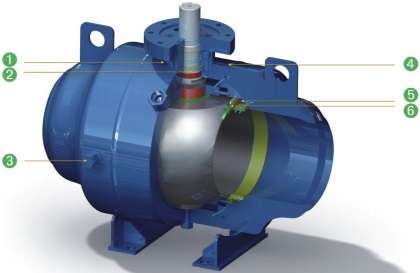

A typical fully welded trunnion mounted ball valve, BW ends, gear operated, forged steel 3 piece split body.

The fully welded trunnion ball valve has a fully welded body which eliminates any possible leakage through body joints hence it is quite suitable for long-distance pipeline transport of oil & gas or low-emission required toxic media as well as buried/ underground service. Generally, Metals Valve’s fully welded ball valves are furnished with butt welding(BW) ends, either soft or metal seated. Flanged end connections RF or RTJ are available upon request. If the valve is used for underground service, extended stem and bonnet will be provided. In order to avoid the heat effect during installation/ welding, extended welding ends can be furnished and post weld heat treatment(PWHT) shall be carefully implemented. Serial Number: FWBV16. See the dimension & weight specifications of FWBV16.

2. Design features and material selection

Design standards: API 6D, ISO 17292, ASME B16.34; Size range: 2″~60″; Pressure ratings: 150LB~2500LB; End connection: ASME B16.5, ASME B16.25; Fire safe design to API 607, API 6FA, ISO 10497; Inspection and test: API 598, API 6D, EN 12266-1. The fully welded trunnion ball valves are designed to full port, forged steel 3-piece split body and side entry, either lever/gear or actuator operated.

Design Features

Design features of fully welded trunnion ball valve, 3 piece split body, side entry, BW ends.

(1) T-shaped blow-out proof stem design.

(2) & (3) Sealant injection fittings to prevent stem or seat leakage in case the internal sealing fails.

(4) Fully welded construction eliminates any possible leakage from body connections.

(5) Fire safe metal to metal design for emergency seals once soft seating materials are disintegrated after fire.

(6) The seat is spring-energized to ensure low-pressure tightness.

Material Selection

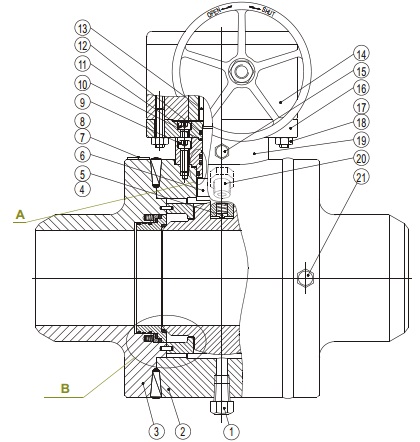

The G.A drawing of fully welded ball valves, trunnion mounted, 3-pc split body, side entry, BW ends.

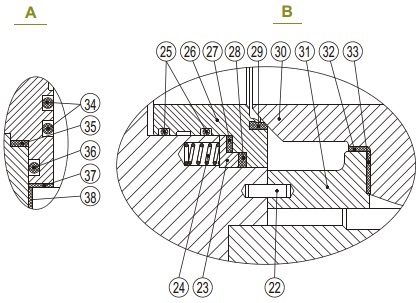

Stem and seat sealing – Zoom View

| Item | Part Name | Carbon Steel | Stainless Steel | Low Temperature |

|---|---|---|---|---|

| 1 | Drain Plug | SS304 | SS304 | SS304 |

| 2 | Body | ASTM A105N | ASTM A182 F316 | ASTM A350 LF2 |

| 3 | Body Cap | ASTM A105N | ASTM A182 F316 | ASTM A350 LF2 |

| 4 | Grounding Plunger | SS301 | SS301 | SS301 |

| 5 | Grounding Spring | SS301 | SS301 | SS301 |

| 6 | Stem | ASTM A105N+ENP | ASTM A182 F316 | ASTM A350 LF2+ENP |

| 7 | Name Plate | Stainless Steel | Stainless Steel | Stainless Steel |

| 8 | Rivet | Stainless Steel | Stainless Steel | Stainless Steel |

| 9 | Screw | ASTM A193 B7 | ASTM A193 B8 | ASTM A320 L7M |

| 10 | Gasket | SS316+Graphite | SS316+Graphite | SS316+Graphite |

| 11 | Screw | ASTM A193 B8 | ASTM A193 B8 | ASTM A320 L7M |

| 12 | O-ring | VITON | VITON | HSN |

| 13 | Stem Key | Carbon Steel | Stainless Steel | Stainless Steel |

| 14 | Gearbox | ASTM A216 WCB | ASTM A216 WCB | ASTM A352 LCB |

| 15 | Stem Injection | SS304 | SS304 | SS304 |

| 16 | Top Flange | ASTM A105N+ENP | ASTM A182 F316 | ASTM A350 LF2+ENP |

| 17 | Actuator Stud | ASTM A193 B7 | ASTM A193 B8 | ASTM A320 L7M |

| 18 | Actuator Nut | ASTM A194 2H | ASTM A194 8 | ASTM A194 7M |

| 19 | Gland Cap | ASTM A105N | ASTM A182 F316 | ASTM A350 LF2 |

| 20 | Vent Valve | Stainless Steel | Stainless Steel | Stainless Steel |

| 21 | Seat Injection | Stainless Steel | Stainless Steel | Stainless Steel |

| 22 | Trunnion Pin | Stainless Steel | Stainless Steel | Stainless Steel |

| 23 | Seat Follower | ASTM A105N+ENP | ASTM A182 F316 | ASTM A350 LF2+ENP |

| 24 | Seat Spring | Inconel X-750 | Inconel X-750 | Inconel X-750 |

| 25 | O Ring | VITON | VITON | HSN |

| 26 | Seat Ring | ASTM A105N+ENP | ASTM A182 F316 | ASTM A350 LF2+ENP |

| 27 | Seat Gasket | PTFE | PTFE | PTFE |

| 28 | Firesafe Gasket | SS316+Graphite | SS316+Graphite | SS316+Graphite |

| 29 | Seat Insert | NYLON | NYLON | NYLON |

| 30 | Ball | ASTM A105N+ENP | ASTM A182 F316 | ASTM A350 LF2+ENP |

| 31 | Trunnion Support | ASTM A216 WCB+ENP | ASTM A351 CF8M | ASTM A352 LCB+ENP |

| 32 | Thrust Washer | RPTFE | RPTFE | RPTFE |

| 33 | Bearing | SS316+PTFE+MoS2 | SS316+PTFE+MoS2 | SS316+PTFE+MoS2 |

| 34 | Stem O-Ring | VITON | VITON | HSN |

| 35 | Gasket | SS316+Graphite | SS316+Graphite | SS316+Graphite |

| 36 | O ring | VITON | VITON | HSN |

| 37 | Thrust Washer | RPTFE | RPTFE | RPTFE |

| 38 | Bearing | SS316+PTFE+MoS2 | SS316+PTFE+MoS2 | SS316+PTFE+MoS2 |