Engineering Specifications of Floating Ball Valves

The engineering specifications of Metals Valve’s floating ball valve series includes the selection of seat & sealing materials’ selection, flow coefficient, as well as its torque values. Metals Valve supplies soft seated floating type ball valves in cast steel, forged steel and stainless steel materials.

Aluminium bronze ball valve, floating type, 4″ 150LB, PTFE soft seat, lever operated. Body & Trim: UNS C95800.

1. Seat material selection of floating ball valves(soft seated).

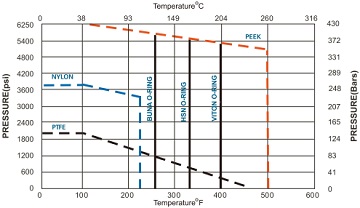

The pressure-temperature ratings of seating and sealing materials including PTFE, Nylon, PEEK, BUNA, Viton and HSN.

| Properties | PTFE | NYLON | PEEK | PCTFE | DEVLON |

|---|---|---|---|---|---|

| Temperature ℉ | -328~428 | -58~248 | -148~500 | -328~302 | -148~302 |

| Temperature ℃ | -200~220 | -50~120 | -100~260 | -200~150 | -100~150 |

| Pressure Ratings(LB) | 150~600 | 150~1500 | 150~2500 | 150~1500 | 150~1500 |

| Hardness | 58 | 72 | 88 | 85 | 78 |

| Tensile Strength(MPa) | 14~34 | 55.2 | 134 | 35.9 | 79.9 |

| Yield Strength(MPa) | 350 | 250 | 2.2 | 150 | 5.4 |

| Specific Gravity(g/cm3) | 2.17 | 1.02 | 1.44 | 2.12 | 1.14 |

| Water Absorption(24hr %) | 0.00 | 1.00 | 0.06 | 0.00 | 0.10 |

| Water Saturation | <0.01 | 1.60 | 0.20 | <0.01 | 3.00 |

2. Sealing materials selection

| Properties | NBR | HNBR | VITON | FFKM | EPDM |

|---|---|---|---|---|---|

| Temperature ℉ | -22~230 | -40~302 | -4~392 | -4~620 | -58~302 |

| Temperature ℃ | -30~110 | -40~150 | -20~200 | -20~327 | -50~150 |

| Specific Density(g/cm3) | 1.31 | 1.34 | 1.85 | 2.00 | 0.87 |

| Hardness(shore A) | 75 | 75 | 75 | 75 | 75 |

3. Flow Coefficient(Cv) and Operating Torque of floating ball valves

Flow Coefficient

| Size | 150LB | 300LB | 600LB | 900LB | 1500LB |

|---|---|---|---|---|---|

| 1/2" | 25 | 25 | 20 | 16 | 16 |

| 3/4" | 56 | 56 | 48 | 34 | 34 |

| 1" | 95 | 95 | 64 | 55 | 55 |

| 1-1/2" | 308 | 308 | 308 | 165 | 165 |

| 2" | 500 | 430 | 370 | 320 | 320 |

| 3" | 1360 | 1100 | 1020 | 920 | - |

| 4" | 2500 | 2000 | 1850 | - | - |

| 6" | 5300 | 5250 | - | - | - |

| 8" | 10750 | 10100 | - | - | - |

| 10" | 17500 | 16820 | - | - | - |

| 12" | 26750 | 25950 | - | - | - |

(1) All sizes are in full port and fully open position.

(2) Pressure ratings shall be in accordance with ASME B16.34.

Operating Torque 01

| Size | 150LB | 300LB | 400LB | 600LB | ||||

|---|---|---|---|---|---|---|---|---|

| inch | N.m | Ft/lbs | N.m | Ft/lbs | N.m | Ft/lbs | N.m | Ft/lbs |

| 1/4" | 5 | 3.69 | 6 | 4.43 | 8 | 5.90 | 12 | 8.86 |

| 3/8" | 5 | 3.69 | 6 | 4.43 | 8 | 5.90 | 12 | 8.86 |

| 1/2" | 6 | 4.43 | 9 | 6.64 | 11 | 8.12 | 16 | 11.81 |

| 3/4" | 10 | 7.38 | 12 | 8.86 | 14 | 10.33 | 20 | 14.76 |

| 1" | 15 | 11.07 | 20 | 14.76 | 29 | 21.40 | 422 | 31.00 |

| 1-1/4" | 32 | 23.62 | 48 | 35.42 | 45 | 33.21 | 60 | 44.28 |

| 1-1/2" | 40 | 29.52 | 60 | 44.28 | 62 | 45.76 | 90 | 66.42 |

| 2" | 50 | 36.90 | 70 | 51.66 | 90 | 66.42 | 130 | 95.94 |

| 2-1/2" | 80 | 59.04 | 90 | 66.42 | 104 | 76.75 | 150 | 110.70 |

| 3" | 90 | 66.42 | 120 | 88.56 | 138 | 101.84 | 200 | 147.60 |

| 4" | 180 | 132.84 | 230 | 169.74 | 255 | 188.19 | 370 | 273.06 |

| 5" | 340 | 250.92 | 420 | 309.96 | - | - | - | - |

| 6" | 840 | 619.92 | 930 | 686.34 | - | - | - | - |

| 8" | 1100 | 811.80 | 1930 | 1424.34 | - | - | - | - |

| 10" | 2000 | 1476.00 | 4500 | 3321 | - | - | - | - |

| 12" | 3200 | 2361.60 | - | - | - | - | - | - |

1. The torque is calculated based on room temperature, with PTFE seats for 150LB~300LB and Nylon for 600LB~1500LB.

2. In cryogenic service, the torque shall be increased by about 2~2.5 times.

3. Torque values listed are used for selection of actuators. Recommended safety factory: 1.3~1.5.

4. The torque may vary in different fluid or with different trim materials.

Operating Torque 02

| Size | 800LB | 900LB | 1500LB | 2500LB | ||||

|---|---|---|---|---|---|---|---|---|

| inch | N.m | Ft/lbs | N.m | Ft/lbs | N.m | Ft/lbs | N.m | Ft/lbs |

| 1/4" | 15 | 11.07 | 15 | 11.07 | 22 | 5.90 | 32 | 23.62 |

| 3/8" | 15 | 11.07 | 15 | 11.07 | 22 | 5.90 | 32 | 23.62 |

| 1/2" | 19 | 14.02 | 20 | 14.76 | 32 | 8.12 | 56 | 41.33 |

| 3/4" | 33 | 24.35 | 35 | 25.83 | 45 | 10.33 | 100 | 73.80 |

| 1" | 65 | 47.97 | 70 | 51.66 | 120 | 21.40 | 190 | 140.22 |

| 1-1/4" | 90 | 66.42 | 100 | 73.80 | 170 | 33.21 | 310 | 228.78 |

| 1-1/2" | 130 | 95.94 | 140 | 103.32 | 189 | 45.76 | 360 | 265.68 |

| 2" | 187 | 138.01 | 200 | 147.60 | 420 | 66.42 | - | - |

| 2-1/2" | 280 | 206.64 | 320 | 236.16 | - | - | - | - |

| 3" | 403 | 297.41 | 431 | 318.08 | - | - | - | - |

1. The torque is calculated based on room temperature, with PTFE seats for 150LB~300LB and Nylon for 600LB~1500LB.

2. In cryogenic service, the torque shall be increased by about 2~2.5 times.

3. Torque values listed are used for selection of actuators. Recommended safety factory: 1.3~1.5.

4. The torque may vary in different fluid or with different trim materials.

CATEGORY AND TAGS: