Flow Direction of Ball Valves

1. Flow direction of conventional ball valves: Bidirectional.

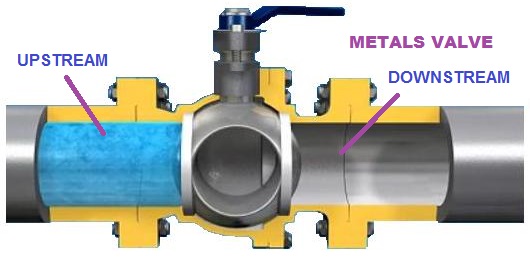

As a rule of thumb, the flow direction of ball valves, no matter it is designed to floating type or trunnion mounted, shall be bidirectional. In the conventional design, two identical round seats are fixed or floating on the upstream and downstream side of the ball. The double-seated ball valve secures a bubble tight shut-off with moderate pressure drops and soft seating materials. Changing direction of the ball valve during installation shall not affect its sealing performance. See the sectional view of a bidirectional floating ball valve:

A typical design of double-seat floating ball valve, sectional view, bidirectional.

2. Unidirectional Ball Valves

However, in project practice, there are some ball valves marked with flow direction arrow on the surface.These ball valves only have one single flow direction and are called as “unidirectional”.

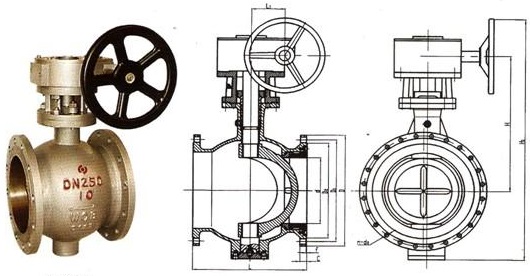

A C-type eccentric ball valve, single seat, unidirectional.

The C ball valve, also known as eccentric ball valve or half ball valve, has a typical single seat design. The C-style half ball design eliminates cleaning dead spot as well as requires a unidirectional installation.

V port ball valve with pneumatic actuator, single seat design, unidirectional flow.

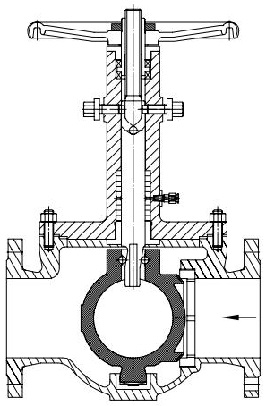

Similar single-seat design is commonly seen in V port ball valves and orbit ball valves both of which limit the valve to unidirectional flow. Usually the single-seat end shall be connected with the upstream flow.

Drawing for the orbit ball valve, handwheel operated, single seat and unidirectional flow.

In term of the working conditions, some double-seats ball valves are also designed to single flow direction. Take cryogenic ball valves used for liquid chlorine and LNG application for example, there is always a pressure relief hole drilled in the ball on the upstream side. This bleeding hole is designed to vent the ball cavity in case the liquid gas vaporizes at an elevated temperature causing over-pressure problems. The cavity relief must be upstream hence it is unidirectional.

Unidirectional cryogenic ball valve, floating type, SS347, 2″ 300LB.