Forged Steel Trunnion Mounted Ball Valve

1. Product Overview

Forged steel trunnion mounted ball valves, 3 piece split body, side entry, gear operated or bare stem with ISO 5211 mounting pad, full bore or reduced bore.

The forged steel trunnion mounted ball valve manufactured by Metals Valve is 3-piece split body and side entry. This series of valves are designed conforming to almost the same standards and codes as that of cast steel trunnion mounted ball valves. The 3-piece body refers to left/right closure parts and the mid body which are all made from forgings. Compared to its cast counterpart, the forged steel body and closure parts eliminate the inevitable defects of casting and drastically improve the microstructure as well as mechanical properties.

2. Design features and material selection

Design standards: API 6D, API 608, BS 5351, ISO 14313, ASME B16.34; Fire safe to API 607, BS 5146, ISO 10497, API 6FA; End connection: ASME B16.5, ASME B16.25, ASME B16.11; Face to face: ASME B16.10; Inspection and test: API 598, API 6D, EN 12266-1. The forged steel trunnion mounted ball valve is available in either full port(FB) or reduced port(RB), 3 piece split body and side entry, lever/gear or actuator operated. Generally, sizes above 4″ are furnished with 4 of supporting legs. Serial No.: FTBV12. See the technical drawing and dimensions of FTBV12.

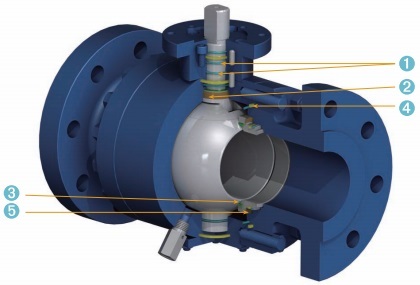

Design Features(≤ 4 inch)

Design features of forged steel 3 piece trunnion mounted ball valve, 4″ and smaller sizes, side entry.

(1) Double sealing O-rings to prevent leakage from stem area.

(2) T-shaped blow-out proof stem design.

(3) Fire safe metal to metal design for emergency seals once soft seating materials are disintegrated after fire.

(4) Gasket & O-ring combined arrangement to prevent leakage from body joints.

(5) Seat spring to exert force on the seat to ensure a tight sealing even at low line pressure.

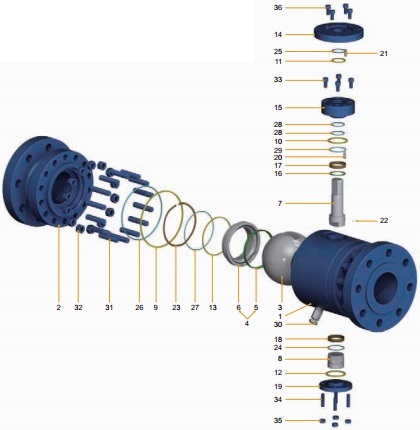

Material Selection(≤ 4 inch)

The 3D explosive view of a forged steel 3 piece trunnion mounted ball valve (for 4″ and smaller sizes).

| Item | Part Name | Standard Material | Stainless Steel | Low-Temp Service |

|---|---|---|---|---|

| 1 | Body | ASTM A105N | ASTM A182 F316 | ASTM A350 LF2 |

| 2 | Body Closure | ASTM A105N | ASTM A182 F316 | ASTM A350 LF2 |

| 3 | Ball | ASTM A105N+ENP | ASTM A182 F316 | ASTM A350 LF2+ENP |

| 4 | Seating | See 5 & 6 | See 5 & 6 | See 5 & 6 |

| 5 | Seat Insert | PTFE/ NYLON/ PEEK | PTFE/ NYLON/ PEEK | PTFE/ NYLON/ PEEK |

| 6 | Seat Ring | ASTM A105N+ENP | ASTM A182 F316 | ASTM A350 LF2+ENP |

| 7 | Stem | ASTM A105N+ENP | ASTM A182 F316 | ASTM A350 LF2+ENP |

| 8 | Trunnion | ASTM A182 F6a | ASTM A182 F316 | ASTM A182 F6a |

| 9 | Gasket | SS316 + Graphite | SS316 + Graphite | SS316 + Graphite |

| 10 | Gasket | SS316 + Graphite | SS316 + Graphite | SS316 + Graphite |

| 11 | Gasket | SS316 + Graphite | SS316 + Graphite | SS316 + Graphite |

| 12 | Gasket | SS316 + Graphite | SS316 + Graphite | SS316 + Graphite |

| 13 | Fire-Safe Seal | SS316 + Graphite | SS316 + Graphite | SS316 + Graphite |

| 14 | Top Flange | ASTM A105N | ASTM A182 F316 | ASTM A350 LF2 |

| 15 | Cover Flange | ASTM A105N | ASTM A182 F316 | ASTM A350 LF2 |

| 16 | Thrust Washer | PTFE | PTFE | PTFE |

| 17 | Bearing | 316SS+PTFE+MoS2 | 316SS+PTFE+MoS2 | 316SS+PTFE+MoS2 |

| 18 | Bearing | 316SS+PTFE | 316SS+PTFE | 316SS+PTFE |

| 19 | Cover | ASTM A105N | ASTM A182 F316 | ASTM A350 LF2 |

| 20 | Pin | Carbon Steel | Stainless Steel | Carbon Steel |

| 21 | Pin | Carbon Steel | Stainless Steel | Carbon Steel |

| 22 | Anti-Static Device | SS304 | SS304 | SS304 |

| 23 | Spring | Inconel X-750 | Inconel X-750 | Inconel X-750 |

| 24 | O-Ring | HNBR/ VITON | HNBR/ VITON | HNBR/ VITON |

| 25 | O-Ring | NBR | NBR | NBR |

| 26 | O-Ring | HNBR/ VITON | HNBR/ VITON | HNBR/ VITON |

| 27 | O-Ring | HNBR/ VITON | HNBR/ VITON | HNBR/ VITON |

| 28 | O-Ring | HNBR/ VITON | HNBR/ VITON | HNBR/ VITON |

| 29 | O-Ring | HNBR/ VITON | HNBR/ VITON | HNBR/ VITON |

| 30 | Vent Valve | Stainless Steel | Stainless Steel | Stainless Steel |

| 31 | Body Stud | ASTM A193 B7 | ASTM A193 B8 | ASTM A320 L7M |

| 32 | Body Nut | ASTM A194 2H | ASTM A194 8 | ASTM A194 7M |

| 33 | Screw | ASTM A193 B7 | ASTM A193 B8 | ASTM A320 L7M |

| 34 | Body Stud | ASTM A193 B7 | ASTM A193 B8 | ASTM A320 L7M |

| 35 | Body Nut | ASTM A194 2H | ASTM A194 8 | ASTM A194 7M |

| 36 | Screw | ASTM A193 B7 | ASTM A193 B8 | ASTM A320 L7M |

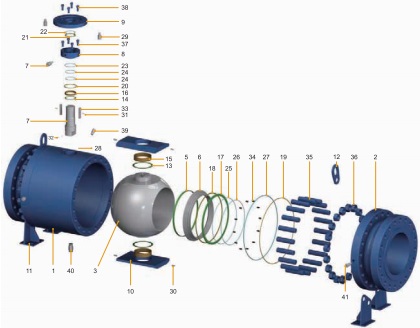

Design Features(> 4 inch)

Design features of forged steel 3 piece trunnion mounted ball valve, side entry, for sizes above 4″.

(1) Double sealing O-rings to prevent leakage from stem area.

(2) & (4) Sealant injection fittings to prevent stem or seat leakage in case the internal sealing fails.

(3) T-shaped blow-out proof stem design.

(5) Fire safe metal to metal design for emergency seals once soft seating materials are disintegrated after fire.

(6) Gasket & O-ring combined arrangement to prevent leakage from body joints.

(7) Preloaded seat spring to exert force on the seat to ensure a tight sealing even at low line pressure.

Material Selection(> 4 inch)

The 3D explosive view of forged steel 3 piece trunnion mounted ball valve, side entry with supporting legs, for sizes above 4″.

| Item | Part Name | Standard Material | Stainless Steel | Low-Temp Service |

|---|---|---|---|---|

| 1 | Body | ASTM A105N | ASTM A182 F316 | ASTM A350 LF2 |

| 2 | Body Cap | ASTM A105N | ASTM A182 F316 | ASTM A350 LF2 |

| 3 | Ball | ASTM A105N+ENP | ASTM A182 F316 | ASTM A350 LF2+ENP |

| 4 | Seating | See 5 & 6 | See 5 & 6 | See 5 & 6 |

| 5 | Seat Insert | PTFE/ NYLON/ PEEK | PTFE/ NYLON/ PEEK | PTFE/ NYLON/ PEEK |

| 6 | Seat Ring | ASTM A105N+ENP | ASTM A182 F316 | ASTM A350 LF2+ENP |

| 7 | Stem | ASTM A105N+ENP | ASTM A182 F316 | ASTM A350 LF2+ENP |

| 8 | Cover Flange | ASTM A105N | ASTM A182 F316 | ASTM A350 LF2 |

| 9 | Top Flange | ASTM A105N | ASTM A182 F316 | ASTM A350 LF2 |

| 10 | Trunnion Support | ASTM A588 B+ENP | ASTM A351 CF3M | ASTM A588 B+ENP |

| 11 | Support Legs | Carbon Steel | Carbon Steel | Carbon Steel |

| 12 | Lifting Lugs | Carbon Steel | Carbon Steel | Carbon Steel |

| 13 | Thrust Washer | PTFE | PTFE | PTFE |

| 14 | Thrust Washer | PTFE | PTFE | PTFE |

| 15 | Bearing | SS316 + PTFE | SS316 + PTFE | SS316 + PTFE |

| 16 | Bearing | SS316 + PTFE + MoS2 | SS316 + PTFE + MoS2 | SS316 + PTFE + MoS2 |

| 17 | Seat Follower | ASTM A105N+ENP | ASTM A182 F316 | ASTM A350 LF2+ENP |

| 18 | Gasket | SS316 + Graphite | SS316 + Graphite | SS316 + Graphite |

| 19 | Gasket | SS316 + Graphite | SS316 + Graphite | SS316 + Graphite |

| 20 | Gasket | SS316 + Graphite | SS316 + Graphite | SS316 + Graphite |

| 21 | Fire Safe Seal | SS316 + Graphite | SS316 + Graphite | SS316 + Graphite |

| 22 | O-Ring | NBR | NBR | NBR |

| 23 | O-Ring | HNBR/ VITON | HNBR/ VITON | HNBR/ VITON |

| 24 | O-Ring | HNBR/ VITON | HNBR/ VITON | HNBR/ VITON |

| 25 | O-Ring | HNBR/ VITON | HNBR/ VITON | HNBR/ VITON |

| 26 | O-Ring | HNBR/ VITON | HNBR/ VITON | HNBR/ VITON |

| 27 | O-Ring | HNBR/ VITON | HNBR/ VITON | HNBR/ VITON |

| 28 | Pin | Stainless Steel | Stainless Steel | Stainless Steel |

| 29 | Pin | Stainless Steel | Stainless Steel | Stainless Steel |

| 30 | Pin | Stainless Steel | Stainless Steel | Stainless Steel |

| 31 | Pin | Stainless Steel | Stainless Steel | Stainless Steel |

| 32 | Anti-Static Device | SS301 | SS301 | SS301 |

| 33 | Key | Stainless Steel | Stainless Steel | Stainless Steel |

| 34 | Spring | Inconel X-750 | Inconel X-750 | Inconel X-750 |

| 35 | Body Stud | ASTM A193 B7 | ASTM A193 B8 | ASTM A320 L7M |

| 36 | Body Nut | ASTm A194 2H | ASTM A194 8 | ASTM A194 7M |

| 37 | Screw | ASTM A193 B7 | ASTM A193 B8 | ASTM A320 L7M |

| 38 | Screw | ASTM A193 B7 | ASTM A193 B8 | ASTM A320 L7M |

| 39 | Vent Valve | Stainless Steel | Stainless Steel | Stainless Steel |

| 40 | Drain Plug | Stainless Steel | Stainless Steel | Stainless Steel |

| 41 | Injection Fitting | Stainless Steel | Stainless Steel | Stainless Steel |

| 42 | Injection Fitting | Stainless Steel | Stainless Steel | Stainless Steel |