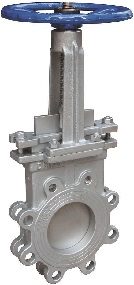

Knife Gate Valve

1. Product Overview

A manually operated knife gate valve, handwheel, lug type, 150LB.

The knife gate valve, also known as “slurry gate valve”, is a special parallel gate valve that is designed to handle slurry, including fibrous material. It has a sharp edge on the bottom of the gate to shear particulates or other solids in suspension as well as to separate slurry. Knife gate valves can be made from various materials covering cast iron, carbon steel, alloy steel and stainless steel. They are widely used in power plant, urban sewage treatment, pulp and paper industry, mining, food and beverage, pharmaceutical, petroleum as well as chemical industries.

Design Standards: MSS SP 81, ASME B16.34, API 598, ASME B16.5, ASME B16.47, BS 5157, JB/T 8691, DIN, JIS, EN standards. Eight series of knife gate valves are available: MTA, MTB, MTC, MTD, MTE, MTF, MTG, MTH.

Design Features: metal or soft seated; yoke & bolted bonnet, through conduit, or bonnetless; wafer type, lug type, flanged type; rising stem or non-rising stem; operation: handwheel, bevel gear, pneumatic actuator, electric actuator, hydraulic actuator, sprocket wheel(chain-wheel); positioning device; short face-to-face length; stable operation, vibration & noise proof; easy maintenance; pressure ratings: 100 psi ~ 500 psi, PN10 ~ PN25; size: 2″ ~ 80″ (DN 50 ~ DN 2000).

2. Optional Operation Methods

| I | II | III | IV |

|  |  |  |

| V | VI | VII | VIII |

|  |  |  |

Manual: I-Handwheel, II-Sprocket(Chain Wheel), III-Lever, IV-Bevel Gear;

Automated: V-Pneumatic, VI-Hydraulic, VII-Electric, VIII-Electric & Hydraulic Hybrid.

3. Conventional Material Selection

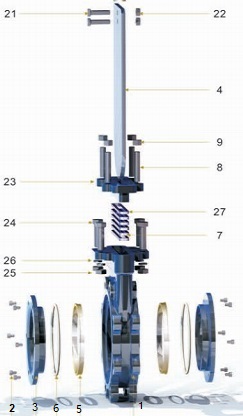

Soft Seal

Explosive View of Soft Seal Knife Gate Valve

|  |

| Item No. | Part Name | Stainless Steel | Carbon Steel |

|---|---|---|---|

| 1 | Body | ASTM A351 CF8M | ASTM A216 WCB |

| 2 | Screw | ASTM A193 B8 | ASTM A193 B7 |

| 3 | Retainer | ASTM A182 F316 | ASTM A105N+ENP |

| 4 | Blade/Gate | ASTM A420 316 | ASTM A420 304 |

| 5 | Seal Ring | RTFE | RTFE |

| 6 | O-Ring | EPDM | EPDM |

| 7 | Packing | PTFE | PTFE |

| 8 | Stud | ASTM A193 B8 | ASTM A193 B7 |

| 9 | Lock Nut | ASTM A194 8 | ASTM A194 2H |

| 10 | Yoke | ASTM A351 CF8 | ASTM A216 WCB |

| 11 | Stem | ASTM A182 F304 | ASTM A182 F6a |

| 12 | Bearing | SS316+PTFE | ASTM 52100 |

| 13 | Sleeve Gland | ASTM A182 F304 | AISI 1035 |

| 14 | Stem Nut | ASTM A439 D2 | ASTM A439 D2 |

| 15 | Handwheel | Ductile Iron | Ductile Iron |

| 16 | Handwheel Nut | ASTM A194 8 | ASTM A194 2H |

| 17 | Stud | ASTM A193 B8 | ASTM A193 B7 |

| 18 | Lock Nut | ASTM A194 8 | ASTM A194 2H |

| 19 | Stopper | SS304 | AISI 1025 |

| 20 | Grease Nipple | SS304 | SS304 |

| 21 | Bolt | ASTM A193 B8 | ASTM A193 B7 |

| 22 | Lock Nut | ASTM A194 8 | ASTM A194 2H |

| 23 | Gland Flange | ASTM A351 CF8 | ASTM A216 WCB |

| 24 | Bolt | ASTM A193 B8 | ASTM A193 B7 |

| 25 | Nut | ASTM A194 8 | ASTM A194 2H |

| 26 | Washer | SS | CS |

| 27 | Patching | EPDM | EPDM |

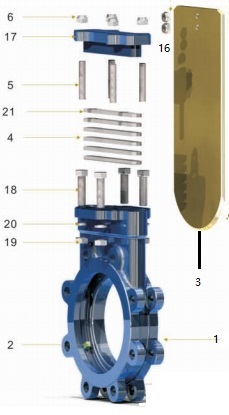

Metal Seal

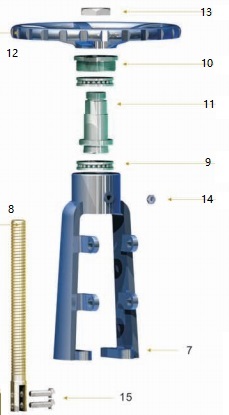

Explosive View of Metal Seal Knife Gate Valve

|  |

| Item No. | Part Name | Stainless Steel | Carbon Steel |

|---|---|---|---|

| 1 | Body | ASTM A351 CF8M | ASTM A216 WCB |

| 2 | Stopper | ASTM A276 316 | ASTM A276 304 |

| 3 | Blade | ASTM A240 316 | ASTM A240 304 |

| 4 | Packing | PTFE | PTFE |

| 5 | Stud | ASTM A193 B8 | ASTM A193 B7 |

| 6 | Lock Nut | ASTM A194 8 | ASTM A194 2H |

| 7 | Yoke | ASTM A351 CF8 | ASTM A216 WCB |

| 8 | Stem | ASTM A182 F304 | ASTM A182 F6a |

| 9 | Bearing | SS316+PTFE | ASTM 52100 |

| 10 | Gland | ASTM A182 F304 | AISI 1035 |

| 11 | Stem Nut | Copper Alloy D-2 | Copper Alloy D-2 |

| 12 | Handwheel | Ductile Iron | Ductile Iron |

| 13 | Handwheel Nut | ASTM A194 8 | ASTM A194 2H |

| 14 | Grease Nipple | Stainless Steel | Carbon Steel |

| 15 | Bolt | ASTM A193 B8 | ASTM A193 B7 |

| 16 | Lock Nut | ASTM A194 8 | ASTM A194 2H |

| 17 | Gland Flange | ASTM A351 CF8 | ASTM A216 WCB |

| 18 | Bolt | ASTM A193 B8 | ASTM A193 B7 |

| 19 | Nut | ASTM A194 8 | ASTM A194 2H |

| 20 | Washer | Stainless Steel | Carbon Steel |

| 21 | Pactching | EPDM | EPDM |

4. Engineering Specification: Torque Value & Thrust Force

Soft Seated

| NPS | 2" | 2-1/2" | 3" | 4" | 6" | 8" | 10" |

| Torque(N*m) | 10 | 12 | 14 | 26 | 27 | 32 | 52 |

| Thrust(KN) | 1.5 | 1.8 | 2.2 | 3.3 | 5.6 | 9.4 | 14.4 |

| NPS | 12" | 14" | 16" | 18" | 20" | 24" | - |

| Torque(N*m) | 68 | 94 | 125 | 154 | 221 | 288 | - |

| Thrust(KN) | 19.1 | 22.7 | 28.5 | 34.8 | 44.5 | 59.5 | - |

1. All torque values are calculated on the basis of room temperature and RTFE seat material.

2. In the case of actuator selection, a safety factor of 1.3~1.5 shall be take into account.

3. Thrust force values are calculated on the basis of 150 psi working pressure.

4. Deviations may exist if line fluid or trim material changes.

Metal Seated

| NPS | 2" | 2-1/2" | 3" | 4" | 6" | 8" | 10" |

| Torque(N*m) | 14 | 18 | 22 | 39 | 25 | 45 | 75 |

| Thrust(KN) | 1.7 | 2.3 | 2.6 | 4.3 | 7.5 | 13.5 | 20.2 |

| NPS | 12" | 14" | 16" | 18" | 20" | 24" | - |

| Torque(N*m) | 101 | 141 | 193 | 237 | 340 | 470 | - |

| Thrust(KN) | 27.7 | 33.8 | 44.0 | 54.6 | 69.1 | 94.8 | - |

1. All torque values are calculated on the basis of room temperature and RTFE seat material.

2. In the case of actuator selection, a safety factor of 1.3~1.5 shall be take into account.

3. Thrust force values are calculated on the basis of 150 psi working pressure.

4. Deviations may exist if line fluid or trim material changes.