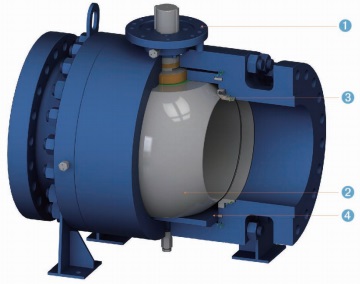

Metal Seated Floating Ball Valve

1. Product overview

A metal seated ball valve, forged steel A105N body, lever operated.

The metal seated floating ball valve refers to a typical floating type ball valve(usually forged steel) which adopts metal to metal contact between the sealing surfaces of the ball and seat. Proper face-hardening process shall be conducted including ultra-sonic spray coating, nickel-based alloy spray welding, stellite spray overlay, as well as ceramic material coating, etc. In order to meet the “zero leakage” sealing requirement, the ball shall be carefully ground to extremely accurate roundness and smoothness by rotating the ball and grinding apparatus in different directions.

2. Specifications of metal seated ball valves

| Technical Drawing & Dimensions for Metal Seated Floating Ball Valve | ||||||

| Class 150 | Class 300 | Class 400 | Class 600 | Class 900 | Class 1500 | Class 2500 |

Design Features

Design features of metal seated floating ball valves, two piece split body, side entry.

Metal seated floating ball valves of Metals Valve are designed to API 6D, API 608, ISO 17292. End connection: RF/RTJ according to ASME B16.5, BW according to ASME B16.25, SW & NPT according to ASME B1.20.1. Valve shall be furnished with blowout proof stem, anti-static device and API 607 fire safe design. Especially,

(1) Top mounting pad design as per ISO 5211. Optional worm gear, electric actuator and pneumatic actuator are available.

(2) Hard faced ball and seat to satisfy the requirement of high hardness, high temperature resistance, and wear resistance.

(3) Under the stress of preloaded spring, a tight sealing is secured even in low operating pressure.

(4) Self-cleaning dust proof seat design is available.

Material Selection

The material selection of metal seated floating ball valves includes body and all trims’ materials which are listed in below table.

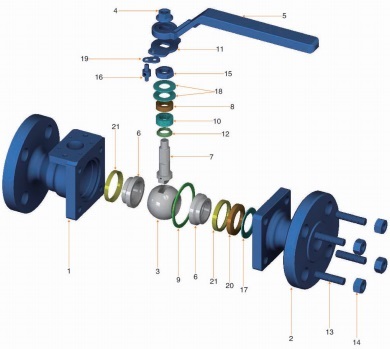

The 3D explosive view of a metal seated floating ball valve, 2 piece split body, side entry.

| Item | Part Name | Standard Materials | Sour Service | Stainless Steel | Low-Temp. Service |

|---|---|---|---|---|---|

| 1 | BODY | ASTM A105N | ASTM A105N | ASTM A182 F316 | ASTM A350 LF2 |

| 2 | BONNET | ASTM A105N | ASTM A105N | ASTM A182 F316 | ASTM A350 LF2 |

| 3 | BALL | A182 F316+WC | A182 F316+WC | A182 F316+WC | A182 F316+WC |

| 4 | LEVER | AISI 1045 | AISI 1045 | ASTM A276 304 | ASTM A276 304 |

| 5 | GLAND FLANGE | AISI 1035 | AISI 1035 | ASTM A276 304 | ASTM A276 304 |

| 6 | SEAT RING | A182 F316+WC | A182 F316+WC | A182 F316+WC | A182 F316+WC |

| 7 | SEAT GLAND | ASTM A182 F316 | ASTM A182 F316 | ASTM A182 F316 | ASTM A182 F316 |

| 8 | STEM | 17-4PH | 17-4PH | 17-4PH | 17-4PH |

| 9 | GLAND | ASTM A182 F304L | ASTM A182 F304L | ASTM A182 F304L | ASTM A182 F304L |

| 10 | THRUST WASHER | A182 F316L+N2 | A182 F316L+N2 | A182 F316L+N2 | A182 F316L+N2 |

| 11 | GASKET | 316+GRAPHITE | 316+GRAPHITE | 316+GRAPHITE | 316+GRAPHITE |

| 12 | PACKING | GRAPHITE | GRAPHITE | GRAPHITE | GRAPHITE |

| 13 | GASKET | GRAPHITE | GRAPHITE | GRAPHITE | GRAPHITE |

| 14 | BOLT | ASTM A193 B7 | ASTM A193 B7M | ASTM A193 B8 | ASTM A320 L7M |

| 15 | SPRING | 17-7PH | 17-7PH | INCONEL X-750 | INCONEL X-750 |

| 16 | STUD | ASTM A193 B7 | ASTM A193 B7M | ASTM A193 B8 | ASTM A320 L7M |

| 17 | NUT | ASTM A193 2H | ASTM A193 2HM | ASTM A194 8 | ASTM A194 7M |

| 18 | COVER FLANGE | ASTM A216 WCB | ASTM A216 WCB | ASTM A182 F316 | ASTM A350 LF2 |

| 19 | PIN | ASTM A276 420 | ASTM A276 420 | ASTM A276 420 | ASTM A276 420 |

| 20 | GASKET | 316+GRAPHITE | 316+GRAPHITE | 316+GRAPHITE | 316+GRAPHITE |

| 21 | STOP PLATE | AISI 1045 | AISI 1045 | ASTM A276 420 | ASTM A276 420 |

| 22 | RETAINER | AISI 1066 | AISI 1066 | ASTM A276 304 | ASTM A276 304 |

| 23 | BOLT | AISI 1035 | AISI 1035 | ASTM A276 304 | ASTM A276 304 |

| 24 | WASHER | AISI 1035 | AISI 1035 | ASTM A276 304 | ASTM A276 304 |

| 25 | PIN | AISI 1035 | AISI 1035 | ASTM A276 304 | ASTM A276 304 |

| 26 | SCREW | AISI 1035 | AISI 1035 | ASTM A276 304 | ASTM A276 304 |

| 27 | LOCK PLATE | ASTM A276 304 | ASTM A276 304 | ASTM A276 304 | ASTM A276 304 |

| 28 | PIN | AISI 1035 | AISI 1035 | ASTM A276 304 | ASTM A276 304 |