Pressure Seal Gate Valve

1. Product Overview

A pressure seal gate valve, cast steel, 900LB.

The pressure seal gate valves supplied by Metals Valve are mainly used in high temperature & high pressure applications such as power-plant steam service. The pressure sealed bonnet-body joint is a more positive way of sealing compared to its bolted bonnet counterparts because the internal pressure of the valve is used for bonnet sealing. As the line pressure is elevated, the load between the sealing surface of bonnet and tapered gasket tends to be increased – the higher the line pressure(valve internal pressure), the greater the sealing force against the bonnet gasket. Hence a more effective sealing can be achieved. Metals Valve’s pressure sealed gate valves are available in cast/forged carbon steel, alloy steel, or stainless steel materials furnished with end connections of butt welding(BW), socket welding(SW) and flanged(RF/RTJ). They are designed as per API 600 and ASME B16.34 covering pressure ratings of Class 600, Class 900, Class 1500, Class 2500. See more technical specifications of pressure sealed gate valves.

2. Design Features

Pressure Seal Design

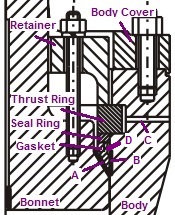

Fig-1: The pressure-seal cross view of high pressure gate valve:segmented thrust ring, seal ring, and metallic gasket.

As illustrated in Fig-1, the pressure sealed bonnet-body joint of a high pressure gate valve is constructed by proper arrangement of body, bonnet, metallic gasket, seal ring, segmental thrust ring, retainer, body cover and a couple of bolts & nuts. The lower end of the bonnet is outwardly sloped to form a sealing contact with the inverted frusto-conical surface of the metallic gasket. The metallic gasket, usually made of soft steel material, is held down by a segmented thrust ring which is inserted into the annular groove of the valve body. The words “segmented” or “segmental” refer to the thrust ring consisting of a plurality of segments all of which may be cut from a single ring. A seal ring made of hard metal is placed between the thrust ring and the gasket and serves to distribute pressure on the thrust ring the gasket preventing deformation of the top surface of the relatively soft gasket. Both the metallic gasket and the seal ring shall be furnished with spaced threaded holes for ease of removing and maintenance. Besides, A – There shall be a 1° angle between mating surfaces of the bonnet slope and the gasket slope. This wedged design ensures a tight seal at either low or high line pressure. B – The interior sealing surface at the body neck shall be welded with a stainless steel inlay to provide finer grain and smooth finish as well as better corrosion resistance. C – Radial bores are furnished in the valve body through which a knock-out pin may be inserted for driving the segmental rings out of the groove. D – A small end bevel on the gasket to prevent it from scraping or catching in the groove.

Seating, Stem, OS&Y

|  |

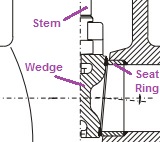

(1) T-shaped blow-out proof design of the stem.

(2) Flexible wedge design to adapt to slightly misalignment caused by internal stress or deformation.

(3) Both the wedge and seat ring shall be hard-faced with ER410 or Stellite 6(Co-Cr A) overlay respectively.

(4) Outside Screw & Yoke, rising stem and non-rising handwheel.

3. Material Selection

C.S & S.S & Low Temp.

| Part Name | Carbon Steel | Low Temp. | Stainless Steel |

|---|---|---|---|

| Handwheel | Ductile Iron | Ductile Iron | Ductile Iron |

| Stem Nut | ASTM A439 D2 | ASTM A439 D2 | ASTM A439 D2 |

| Yoke | ASTM A216 WCB | ASTM A352 LCB | ASTM A351 CF8M |

| Packing | Graphite | Graphite | Graphite |

| Body | ASTM A216 WCB | ASTM A352 LCB | ASTM A351 CF8M |

| Bonnet | ASTM A105 | ASTM A350 LF2 | ASTM A182 F316 |

| Wedge | ASTM A216 WCB+ER410 | ASTM A352 LCB+ER410 | ASTM A351 CF8M+STL 6 |

| Seat Ring | ASTM A105+ STL 6 | ASTM A350 LF2+STL 6 | ASTM A182 F316+STL 6 |

| Stem | ASTM A182 F6a | ASTM A182 F6a | ASTM A182 F316 |

| Retainer | ASTM A105 | ASMT A350 LF2 | ASTM A276 420 |

| Body Cover | ASTM A216 WCB | ASTM A352 LCB | ASTM A351 CF8M |

| Segmental Thrust Ring | ASTM A105 | ASTM A350 LF2 | ASTM A276 420 |

| Bonnet Seal Ring | AISI 1045 | ASTM A276 420 | ASTM A276 420 |

| Bonnet Gasket | ASTM A182 F304 | ASTM A182 F304 | ASTM A182 F316L |

| Bonnet Stud | ASTM A193 B7 | ASTM A320 L7M | ASTM A193 B8 |

| Bonnet Nut | ASTM A194 2H | ASTM A194 7M | ASTM A194 8 |

| Yoke Stud | ASTM A193 B7 | ASTM A320 L7M | ASTM A193 B8 |

| Yoke Nut | ASTM A194 2H | ASTM A194 7M | ASTM A194 8 |

| Eyebolt | ASTM A193 B7 | ASTM A320 L7M | ASTM A193 B8 |

| Gland Flange | ASTM A105 | ASTM A350 LF2 | ASTM A182 F316 |

| Gland | ASTM A276 420 | ASTM A276 316 | ASTM A276 316 |

| Gland Nut | ASTM A194 2H | ASTM A194 7M | ASTM A194 8 |

| Bearing | SS316 + PTFE | SS316 + PTFE | SS316 + PTFE |

| Name Plate | SS304 | SS304 | SS304 |

| Rivet | Copper | Copper | SS304 |

2. Body materials listed in this table are cast steel. Forged steel body can be provided upon request.

3. Bonnet materials are furnished in forged steel to provide finer grain structure for a tight seal.

4. For sizes 4" and smaller, the bonnet gasket shall be made of graphite.

High Temperature Alloy Steel

| Part Name | 1-1/4Cr-1/2Mo | 2-1/4Cr-1Mo | Cr-Mo-V |

|---|---|---|---|

| Handwheel | Ductile Iron | Ductile Iron | Ductile Iron |

| Stem Nut | ASTM A439 D2 | ASTM A439 D2 | ASTM A439 D2 |

| Yoke | ASTM A216 WCB | ASTM A216 WCB | ASTM A216 WCB |

| Packing | Graphite | Graphite | Graphite |

| Body | ASTM A217 WC6 | ASTM A217 WC9 | ASTM A217 C12A |

| Bonnet | ASTM A182 F11 | ASTM A182 F22 | ASTM A182 F91 |

| Wedge | ASTM A217 WC6+ER410 | ASTM A217 WC9+ER410 | ASTM A217 C12A+ER410 |

| Seat Ring | ASTM A182 F11+STL6 | ASTM A182 F22+STL6 | ASTM A182 F91+STL6 |

| Stem | ASTM A182 F6a | ASTM A182 F6a | ASTM A182 F6a |

| Retainer | AISI 4140 | AISI 4140 | AISI 4140 |

| Segmental Thrust Ring | AISI 4140 | AISI 4140 | AISI 4140 |

| Pressure Ring | AISI 4140 | AISI 4140 | AISI 4140 |

| Bonnet Gasket | ASTM A182 F304 | ASTM A182 F304 | ASTM A182 F304 |

| Bonnet Stud | ASTM A193 B16 | ASTM A193 B16 | ASTM A193 B16 |

| Bonnet Nut | ASTM A194 4 | ASTM A194 4 | ASTM A194 4 |

| Yoke Stud | ASTM A193 B16 | ASTM A193 B16 | ASTM A193 B16 |

| Yoke Nut | ASTM A194 4 | ASTM A194 4 | ASTM A194 4 |

| Eyebolt | ASTM A193 B16 | ASTM A193 B16 | ASTM A193 B16 |

| Gland Flange | ASTM A276 420 | ASTM A276 420 | ASTM A276 420 |

| Gland | ASTM A276 420 | ASTM A276 420 | ASTM A276 420 |

| Gland Nut | ASTM A194 4 | ASTM A194 4 | ASTM A194 4 |

| Bearing | SS316 + PTFE | SS316 + PTFE | SS316 + PTFE |

| Name Plate | SS304 | SS304 | SS304 |

| Rivet | SS304 | SS304 | SS304 |

1. C-Mo, Cr-Mo, Cr-Mo-V, Ni-Cr-Mo, & Cr-Fe high-temperature alloy steels:

Cast: ASTM A217 WC1; WC6, WC9, WC11, C5, C12; C12A; WC4, WC5; CA15.

Forged: ASTM A182 F1, F11, F22, F5, F9, F91.

2. Forged steel materials are preferable for body & bonnet due to the finer grain structure.

3. Other materials are available upon request.