Through Conduit Gate Valve

1. Product Overview

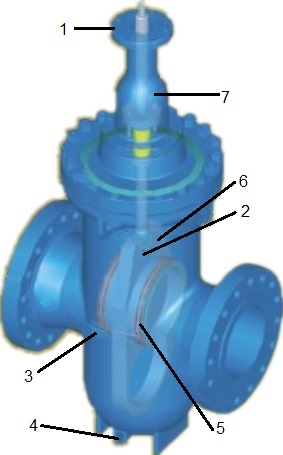

A typical through conduit gate valve, slab type, WCB body, bevel gear operated.

The through conduit gate valve is a typical parallel gate valve. Metals Valve supplies through conduit gate valves in two series: slab gate and expanding gate. The closure member(gate/disc) of a through conduit slab gate valve is a slab of metal with a porthole at the bottom. It is provided with floating seats that are spring energized and forced against the disc by fluid pressure. When the valve is fully open, the porthole in the disc engages the valve flow passage port. When the valve is fully closed, the upper solid part of the slab blocks up the valve flow like a blind flange. The through conduit expanding gate valve is developed on the basis of slab gate valve. Instead of one “slab”, the disc consists of two halves with a wedge-shaped interface. Both the female and male gates are provided with complementary opposed inner faces, each formed with two angular-related surface portions diverging transversely. The two halves(gates) are interlinked so that they wedge apart when being moved into the fully open or closed positions, but relax in the intermediate position during the disc travelling stroke. The wedge mechanism ensures tight seal on both upstream and downstream seating surfaces even at low pressure levels. Through conduit gate valves are widely used in oil & gas, petrochemical, power plant and mining industries.

2. Design Features

Illustration of design features of through conduit gate valves.

Design Standards: API 6D; ASME B16.5 & ASME B16.47; ASME B31.4, ASME B31.8. End Connections:RF, RTJ, BW. Rising stem, full port, double block & bleed(DBB), bidirectional seating. Operation: Handwheel, Gear, Actuators.

(1) The ISO 5210 mounting pad are provided to facilitate convenient actuator installation.

(2) Venting valve installed to avoid over pressure inside the body-bonnet cavity.

(3) Emergency sealant injection fitting to prevent leakage in case of seating seal’s failure.

(4) Drain plug to release the residue within body cavity.

(5) Spring-energized seats with double O-rings to ensure efficient sealing even at low pressure.

(6) Special HVOF process for the gate: Electric Nickel Plate(ENP), Tungsten Carbide Overlay(TC), Stellite No.6 overlay.

(7) Emergency sealant injection fitting to ensure stem sealing.

3. Technical Drawing & Material Selection

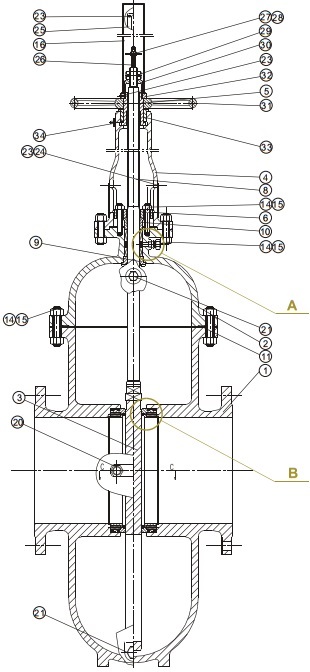

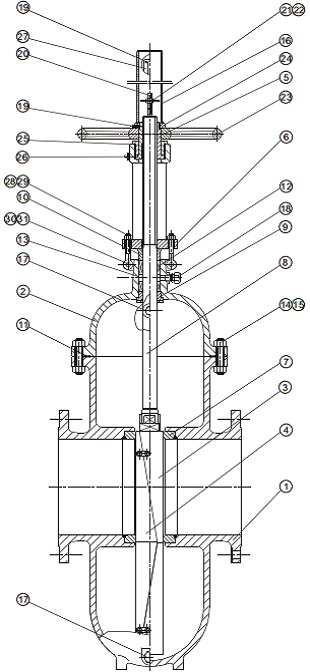

Technical Drawing of Slab Gate

The technical drawing of throught conduit slab gate valve.

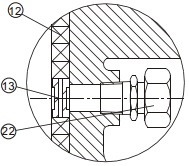

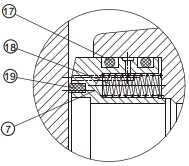

| Detail View A-A | Detail View B-B |

|  |

Material Selection for Slab Gate

| No. | Part | Standard | Low Temp. |

|---|---|---|---|

| 1 | Body | ASTM A216-WCB | ASTM A352-LCB |

| 2 | Bonnet | ASTM A216-WCB | ASTM A352-LCB |

| 3 | Gate | ASTM A105/ENP | ASTM A350-LF2/ENP |

| 4 | Yoke | ASTM A216-WCB | ASTM A352-LCB |

| 5 | Stem Nut | ASTM A439 D-2 | ASTM A439 D-2 |

| 6 | Gland Flange | ASTM A216-WCB | ASTM A352-LCB |

| 7 | Seat Ring | ASTM A105/ENP | ASTM A350-LF2/ENP |

| 8 | Stem | ASTM A182-F6a | ASTM A182-F316 |

| 9 | Back Seat | ASTM A276-420 | ASTM A182-F316 |

| 10 | Gland | ASTM A276-420 | ASTM A182-F316 |

| 11 | Gasket | 316SS+Graphite | 316SS+Graphite |

| 12 | Packing | Graphite | Graphite |

| 13 | Lantern Ring | ASTM A276-420 | ASTM A182-F316 |

| 14 | Stud | ASTM A193-B7M | ASTM A320-L7M |

| 15 | Nut | ASTM A194-2HM | ASTM A194-7M |

| 16 | Stem Enclosure | Carbon Steel | Carbon Steel |

| 17 | O-Ring | NBR | NBR |

| 18 | Spring | Inconel X-750 | Inconel X-750 |

| 19 | Seat Insert | PTFE | PTFE |

| 20 | Seat Injection | Assembly | Assembly |

| 21 | Plug | Carbon Steel | S.S. |

| 22 | Stem Injection | Assembly | Assembly |

| 23 | Screw | Carbon Steel | Carbon Steel |

| 24 | Yoke Enclosure | Carbon Steel | Carbon Steel |

| 25 | Class Cover | Plexiglass | Plexiglass |

| 26 | Indicate Bar | ASTM A276-420 | S.S. |

| 27 | Nut | Carbon Steel | Carbon Steel |

| 28 | Indicate Plate | ASTM A276-420 | S.S. |

| 29 | Split Pin | Carbon Steel | Carbon Steel |

| 30 | Retaining Nut | Carbon Steel | Carbon Steel |

| 31 | Handwheel | Ductile Iron | Ductile Iron |

| 32 | Handwheel Nut | Carbon Steel | Carbon Steel |

| 33 | Retaining Nut | Carbon Steel | Carbon Steel |

| 34 | Grease Fitting | Assembly | Assembly |

Technical Drawing of Expanding Gate

The technical drawing of throught conduit double expanding gate valve.

Material Selection for Expanding Gate

| No. | Part | Standard | Low Temp. |

|---|---|---|---|

| 1 | Body | ASTM A216-WCB | ASTM A352-LCB |

| 2 | Bonnet | ASTM A216-WCB | ASTM A352-LCB |

| 3 | Gate1 | ASTM WCB-CR13 | ASTM LCB+316 |

| 4 | Gate2 | ASTM WCB-CR13 | ASTM LCB+316 |

| 5 | Stem Nut | ASTM A439 D-2 | ASTM A439 D-2 |

| 6 | Gland Flange | ASTM A216-WCB | ASTM A352-LCB |

| 7 | Seat Ring | ASTM A105+STL | ASTM F316+STL |

| 8 | Stem | ASTM A182-F6a | ASTM A182-F316 |

| 9 | Back Seat | ASTM A276-420 | ASTM A182-F316 |

| 10 | Gland | ASTM A276-420 | ASTM A182-F316 |

| 11 | Gasket | 316SS+Graphite | 316SS+Graphite |

| 12 | Packing | Graphite | Graphite |

| 13 | Lantern Ring | ASTM A276-420 | ASTM A182-F316 |

| 14 | Stud | ASTM A193-B7 | ASTM A320-L7M |

| 15 | Nut | ASTM A194-2H | ASTM A194-7M |

| 16 | Stem Enclosure | Carbon Steel | Carbon Steel |

| 17 | Plug | Carbon Steel | S.S. |

| 18 | Stem Injection | Assembly | Assembly |

| 19 | Screw | Carbon Steel | Carbon Steel |

| 20 | Indicate Bar | ASTM A276-420 | S.S. |

| 21 | Nut | Carbon Steel | Carbon Steel |

| 22 | Indicate Plate | ASTM A276-420 | S.S. |

| 23 | Handwheel | Ductile Iron | Ductile Iron |

| 24 | Handwheel Nut | Carbon Steel | Carbon Steel |

| 25 | Retaining Nut | Carbon Steel | Carbon Steel |

| 26 | Grease Fitting | Assembly | Assembly |

| 27 | Glass Cover | Plexiglass | Plexiglass |

| 28 | Eye Bolt | ASTM A193-B7 | ASTM A320-L7M |

| 29 | Nut | ASTM A194-2H | ASTM A194-7M |

| 30 | Pin | Carbon Steel | Carbon Steel |

| 31 | Split Pin | Carbon Steel | Carbon Steel |